Capabilities

Hot Forging, Warm Forging, Cold Forging

Author: Ideal | Release time: 2020-05-31

Timely and Efficient Processing, and Accurate Order Delivery

Founded in 1998, Qingdao Ideal Metalware is a fully integrated forging manufacturer that positions itself as a customer’s one-stop source for Forging, Machining, Heat Treating, and Surface Treating services in supplying high quality Industrial Components and Lifting & Rigging Hardware products.

INDUSTRIES & MARKETS

Since the company’s foundation, both our standard and custom forgings are applied in a wide range of industries, such as Food Machinery, Medical Equipment, Automotive, Off-highway, Construction Machinery, Mining Machinery, Turbine, Electronic Devices, Hydraulic Cylinders & Valves, Recycling Equipment, Petroleum Machinery, and General Equipment Manufacturing, etc.

FACILITIES & EQUIPMENT

The factory equipped with a full line of forging and machining equipment with all necessary support equipment. Continual investments in facilities and equipment enable us to stay in step with emerging stringent requirements, and our vast metallurgical expertise allows us to achieve greater flexibility in offering the best solution for customer’s forging projects of a variety of shapes, geometries, and sizes.

MATERIALS

The raw materials used at our Forging include Carbon Steel, Alloy Steel, Stainless Steel, Nickel Alloys, Aluminum, Brass & Copper, Duplex & Super Duplex, Heat Resisting Alloys, Non-ferrous, and more.

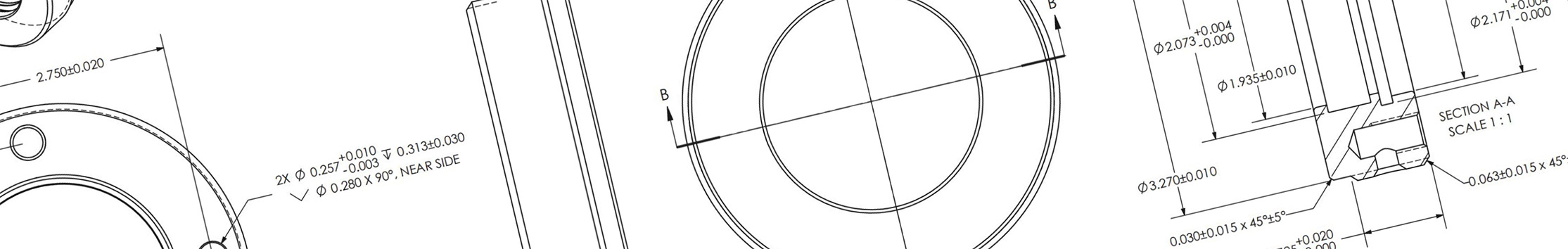

CNC MACHINING

Equipped with a range of CNC machining equipment, we are capable of performing various complex machining services on the forged products we manufacture. The machinery provides significant turning, milling, and drilling capacity for rough to finish machining of forgings. Highly skilled personnel provide an optimal cost-effective solution with the high level of standards for the machining projects.

QUALITY MANAGEMENT

To ensure the consistent quality, the forging facilities established stringent processes and monitoring practices and are certified with the ISO900:2015 to meet international standards.

From the raw material, through engineering, die creation, fabrication, testing, and shipment, every forging order is handled with a level of quality that comes from years of attention to detail. With our dedicated personnel and quality management system, our quality assurance department guarantees our production meets the required specification.

Chemical and mechanical properties of every forgings are fully traceable to the original forging lot and raw material heat. And Material Certifications are available upon request for each shipment.

TESTING & INSPECTIONS

We perform needed testing and inspections to ensure the parts meet all the applicable specifications and standards, in addition to customer requirements.

Based on differences of the materials and the intended service of the parts, the following testing of destructive or nondestructive methods will be provided accordingly:

- Mechanical testing

- Magnetic Particle Testing

- Liquid Penetrant Testing

- Chemical Analysis

- Corrosion and metallurgical evaluations

We always strive to innovate and improve processes to stay competitive in satisfying our customer’s expectations, and our goal is to provide customers with the best quality and service available in the forging industry.

Working with Qingdao Ideal Metalware will be the right choice.

We sincerely invite you to sit around the Drawings with us, and determine the best solution for maximizing the value of your project.

We are always ready to serve you. Please contact us at any time.

Prev : CNC Milling, CNC Turning, CNC Drilling

Next : There isn't next