Capabilities

Quality Controls, Tests & Inspections

Author: Ideal | Release time: 2020-06-05

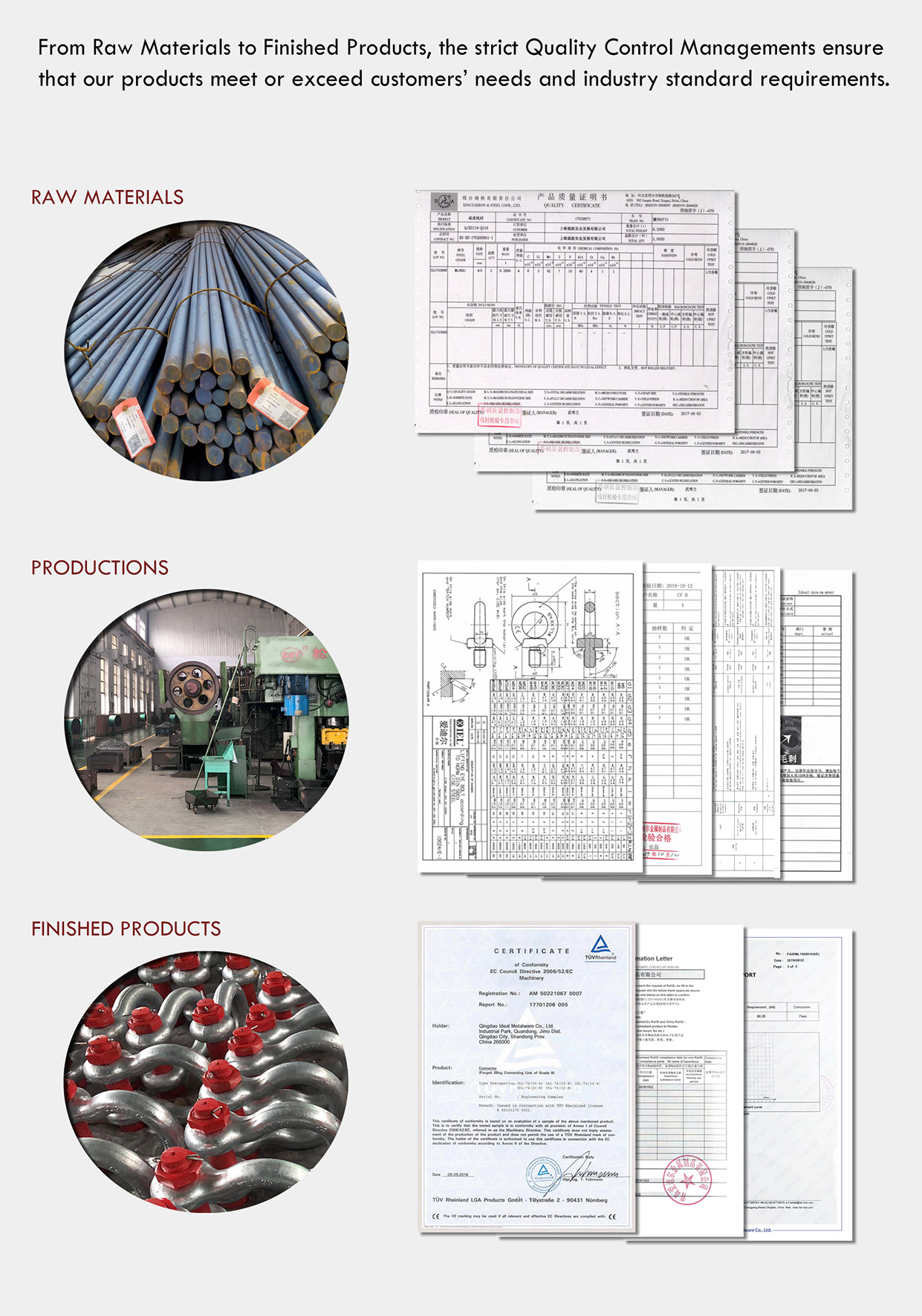

To ensure the consistent quality, Qingdao Ideal Metalware established stringent processes and monitoring practices and are certified with the ISO900:2015 to meet international standards.

From the raw material, through engineering, die creation, fabrication, testing, and shipment, every forging order is handled with a level of quality that comes from years of attention to detail. With our dedicated personnel and quality management system, our quality assurance department guarantees our production meets the required specification.

Chemical and mechanical properties are fully traceable to the original lot and raw material heat, and Material Certifications are available for each shipment.

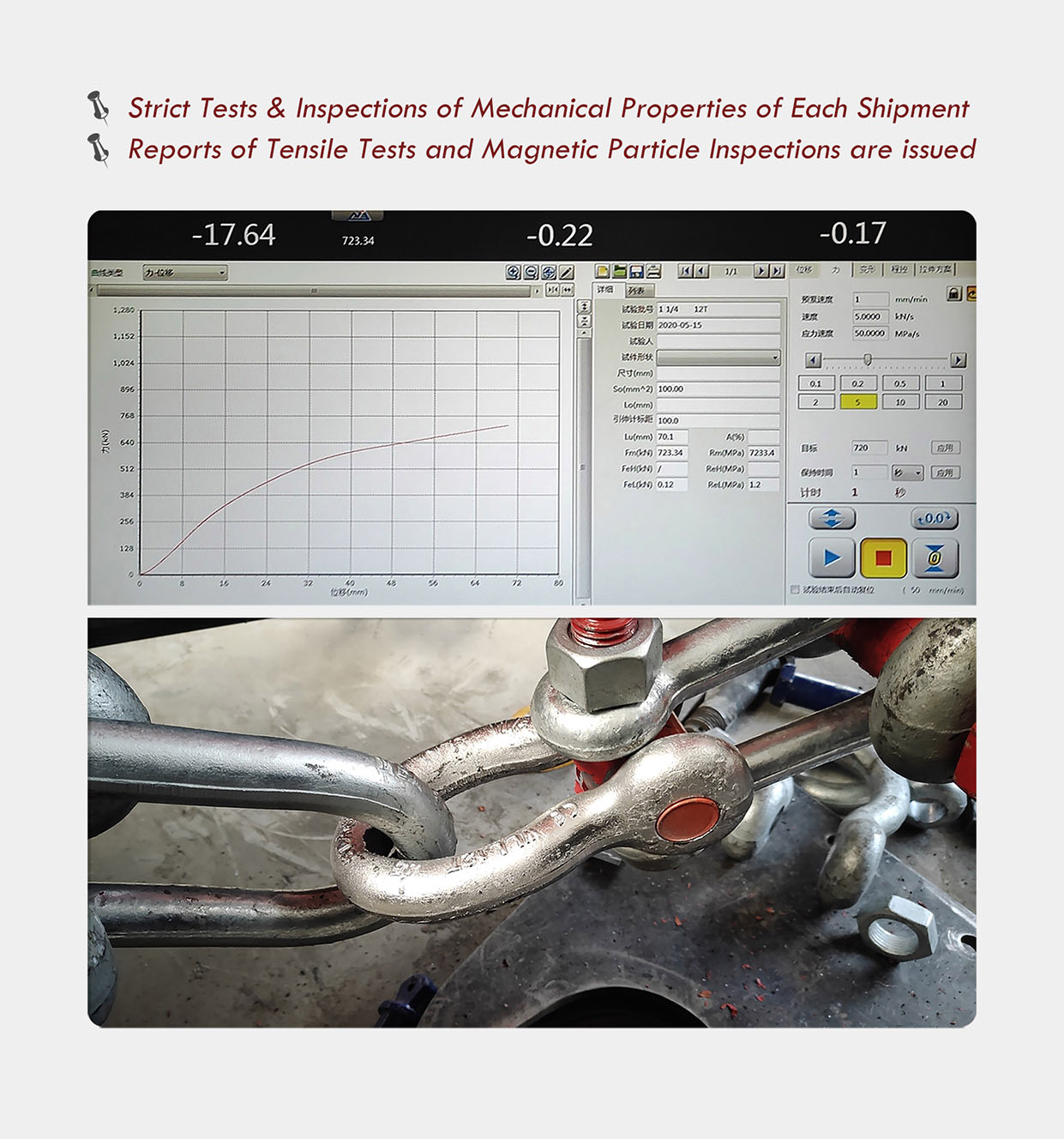

TESTING & INSPECTIONS

We perform needed testing and inspections to ensure the parts meet all the applicable specifications and standards, in addition to customer requirements. Third-Party Tests/Inspection Reports are available per requests.

Based on differences of the materials and the intended service of the parts, the following testing of destructive or nondestructive methods will be provided accordingly:

- Mechanical testing (tensile, hardness, impact test)

- Magnetic Particle Testing

- Liquid Penetrant Testing

- Chemical Analysis

- Corrosion and metallurgical evaluations

Prev : Quality Control

Next : Powder Coating